Laboratory

S.R.C. Engineering helps in developing or improving ceramic recipes mainly for sanitary-ware bodies and glaze to reach higher yield and quality standards, starting from client's raw materials or by sourcing new ones.

Know How transfer for laboratory production methodology and, when required, for the entire process, have been provided to several factories worldwide and where it can be seen some of S.R.C. lab tools provided or realized on own drawings on board of the company services, that means S.R.C. has been there.

Pfefferkorn plasticity test

Example of tests based on

S.R.C. Engineering methodology

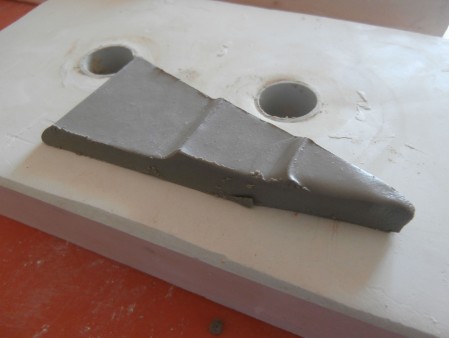

Bending - deformation test

Routine or specific tests on green and on fired materials include particle size analysis, rheological analysis, mechanical, thermal and microscope tests, allowing to completely characterize all of client's materials thanks to the company experiences developed in more than 70 years of activity.

Casting rate test

This full range of controls, related methodology and their set up when necessary in on-site labs, is transferred to the client's personnel who is assisted in implementing the system, allowing a full remote monitoring of the results applied to industrial productions.

Casting rate specimen

S.R.C. Engineering methodology is based on many practical meaningful and instrumental tests which all together give a detail guideline on how to proceed to reach the targets. Monitoring of factories performances worldwide from Japan to Ecuador, from Siberia to Saudi Arabia, from South Africa to Algeria, from Poland to China, the latter where the first Mr Grassi's actions started in 80s', have been provided in many years of activity.

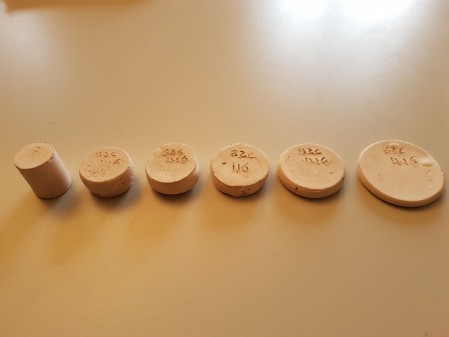

Specimen for fired M.O.R. test by Michaelis scale

S.R.C. Engineering method

S.R.C. Engineering method

Plasticity test specimen

Glaze viscosity test before firing

Baroid press for pressure casting test